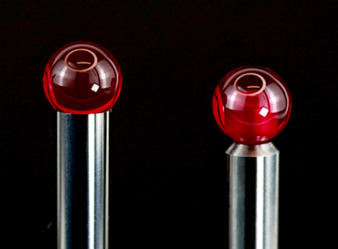

An automated and reliable vacuum brazing process produces a high-quality ball-socket connection with maximum strength, load capacity and a long product life. The solid ball is brazed into the calotte with a defined amount of solder and the optimum result is achieved at around 800°C.

Highest precision.

Maximum strength.

Enormous load capacity.

Long product life.

Appealing appearance.

Reliable process.

Highest precision.

Maximum strength.

Enormous load capacity.

Long product life.

Appealing appearance.

Reliable process.

A solid ruby sphere is particularly stable as it is not subject to the external stresses that occur during the production of spherical bores.

In addition, crystals break out less frequently and the risk of scratches is significantly lower as the mechanical drilling process is eliminated. These advantages are particularly important for small ball diameters.

A vacuum-brazed connection is resistant to temperature and chemicals. It remains stable in the long term and therefore ensures a high level of process reliability. Even thin shafts with small balls can be joined extremely stably in this way.

The connection in a calotte prevents air inclusions. Vacuum brazing technology enables a high-quality and visually appealing connection.

The vacuum-brazed connection between the ball and shaft cannot loosen unnoticed. The ball is either firmly connected to the shaft or not. In contrast, adhesive connections can more easily come loose, which can affect the measuring accuracy. The vacuum-brazed connection, on the other hand, ensures constant measuring conditions and minimizes measuring errors.