Experience and expertise in styli business.

Custom made or in large series.

In great variety.

Close and straightforward cooperation.

Reliable partnership and fast delivery.

Production and assembly in Germany's most innovative region.

We offer precision styli for tactile measurements on CMM, accessories such as extensions, cubes, adapters, and tools as well as styli designed for measuring form and contour. In addition, you can find styli for use on production machines and original manufacturer parts and accessories for measuring machines.

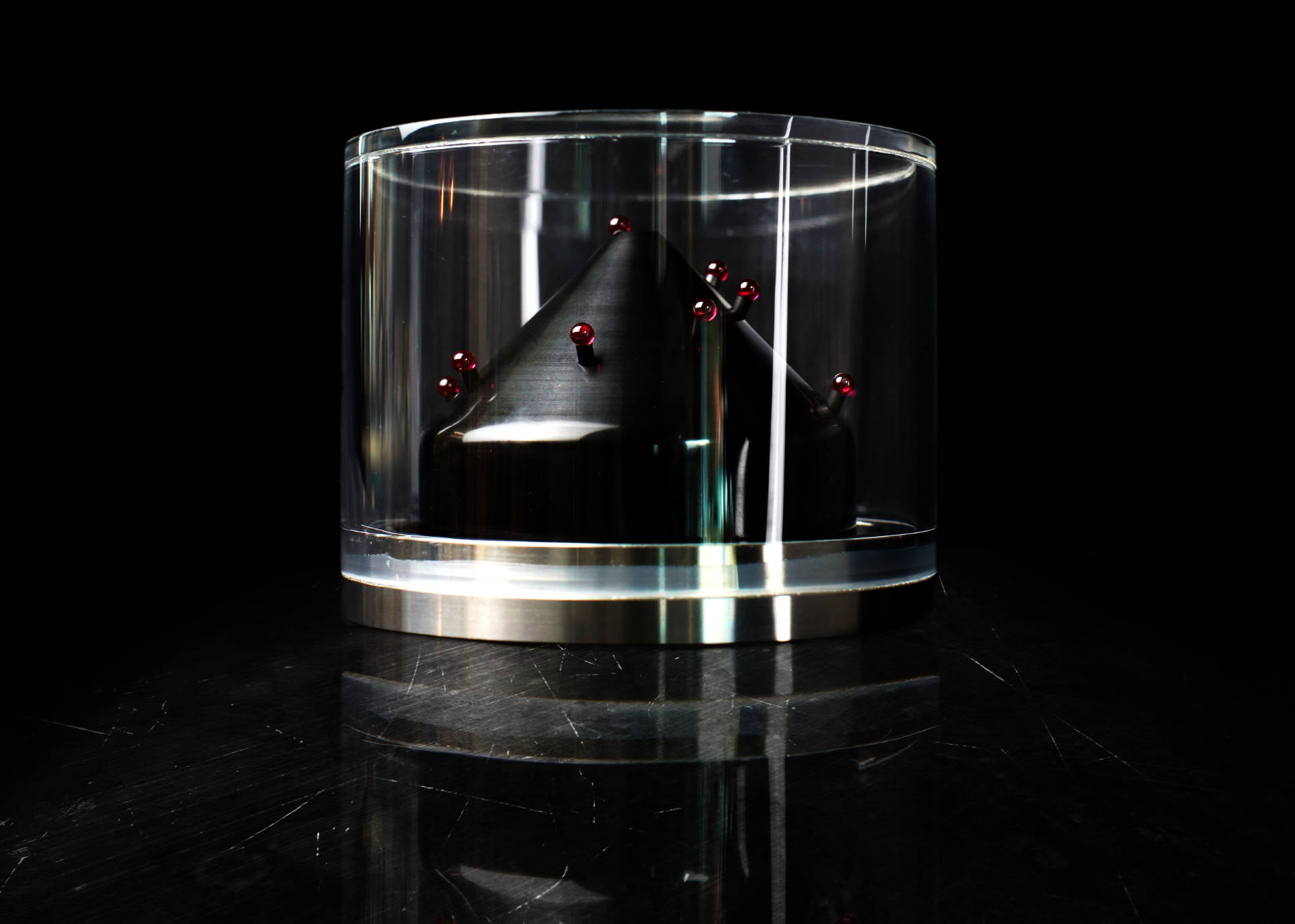

Test specimen CT-Check with spheres for quick inspection of a CT system. Including DAkkS calibration and certificate with tactile reference values for fast accuracy monitoring of the CT system.

GOEKELER combines an innovative start-up spirit with continuity and reliability. We have been working together since 2011 and are convinced of the quality of the styli.

HAIYAN ZHAO

Bosch Powertrain Systems

A stylus is a component of measuring systems, in particular coordinate measuring machines (CMM) and machine tools, which is used for tactile scanning of workpieces. It is the element that has direct contact with the surface of the workpiece to be measured in order to detect precise positions, distances and geometric features.

A stylus consists of at least a shaft and a stylus ball. GOEKELER offers an extensive selection and a wide variety of designs. Your workpiece to be measured determines the stylus type and the required size, whereby maximum rigidity of the stylus and a perfect ball shape are decisive. A correctly selected and calibrated stylus is crucial for the accuracy and reliability of the measuring process. The quality of GOEKELER styli will make the difference for your measurement results. By choosing a GOEKELER stylus, you are not making any compromises.

Straight styli are the most commonly used type of styli and at the same time the simplest styli, equipped with high-precision ruby, silicon nitride, ceramic, carbide or diamond-coated balls and shafts made of various materials such as carbide, ceramic and carbon fibre. The ball diameter and measuring length depend on the size of the workpiece to be measured.

Star styli consist of styli combined in a star shape and enable measurements in different coordinate directions. They are used to measure complex features and bores. Star styli are very flexible and save time, as they allow different probing and measuring processes without changing styli.

Disc styli are suitable for measuring recesses and recesses in bores. They are made from a ball and are available in various diameters and thicknesses. Measuring with a disc probe is similar to measuring with a large stylus ball, but only a small section of the ball surface is available. Thin discs require careful angular alignment for correct contact.

Cylinder styli are used to measure holes in sheet metal parts, pressed parts and thin workpieces. In addition, various thread characteristics can be measured and the centres of threaded holes can be determined. Cylindrical inserts with a radius are also suitable for measuring surfaces.

T-Styli and L-Styli have two or one stylus ball at a 90° angle to the shaft. They are used for measuring undercuts or for scanning the underside of the workpiece. T-styli are particularly suitable for measuring opposing undercuts, such as grooves. With GRD Styli, the angle can be defined individually. This allows measuring inclined bores and surfaces.

To ensure high measuring accuracy, it is important to choose the stylus as short as possible. The less a stylus can be bent, the more accurate the measurement results will be. It is also best to keep the number of individual parts at a minimum. Each additional extension increases the risk of the stylus bending or deviating in position. When choosing the ball, the bigger the better. This increases the ball-to-shaft ratio and minimises the risk of faulty shaft probing and the effects of the workpiece's surface finish.

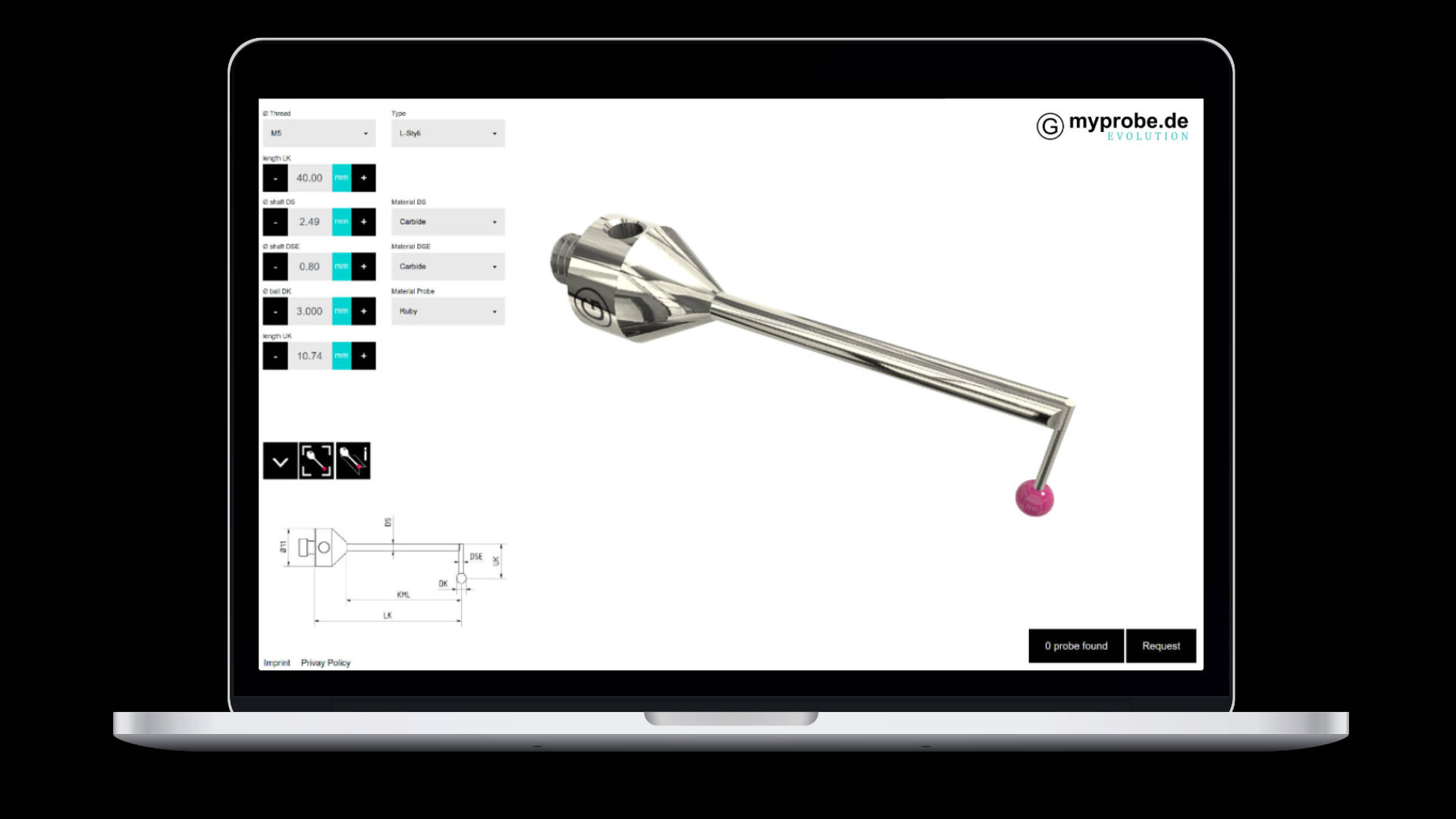

We have the right stylus for every measuring task. You will find over 600 standard styli in our shop. If you can't find what you're looking for here, you can configure customised special probes in our configurator. We can manufacture almost any conceivable variant for you and will of course be happy to advice.

Vacuum brazing is a process in which brazed joints are produced under vacuum conditions. We are the first manufacturer in the world to produce the entire styli portfolio using this technology. An automated and reliable process that ensures maximum strength and stability of the ball-socket connection.

The special feature of vacuum brazing is the high quality of the brazed joints, which is achieved by avoiding oxidation and air inclusions in the brazing process, thus guaranteeing reliable tactile measurement. Unlike other conventional manufacturing processes, the ball does not have a drilled hole and cannot easily come loose and thus falsify the measurement result. The reliable soldered connection ensures high measurement repeatability and the durability of our styli.

PEOPLE.POWER.PIONEERS.